CLANTECH offers the engineering services required in projects related to industrial gases (H2, O2, N2), from their conception to their execution and commissioning. To this end, Clantech has a multidisciplinary technical team with vast experience in the sector.

Engineering

COMPETENCIES

Consultancy services

- Process Pre design.

- Techno-economic feasibility studies and market analysis.

- Support in tendering phase.

- Analysis and recommendations of different manufacturers.

- Analysis and recommendations of different technologies.

- Optimisation of the initial solution.

Conceptual, basic and detailed engineering

- Development of the different engineering phases of an industrial project (conceptual, basic and detailed).

- List of customized documentation according to client’s requirements.

- Multidisciplinary engineering team: process, mechanical, piping, instrumentation and control, electrical and safety.

- Owner Engineering Services.

Permitting

- Technical support along the Project authorization phases.

- Definition of critical documentation and permitting roadmap.

- Follow up of authorization process.

Purchasing management

- Development of technical specification for quotation (RFQ).

- Bid comparison.

- Activation of orders.

- Vendor document review.

- Purchase order follow up.

- Factory Inspections (FAT).

Project management

- Coordination with contractors.

- Control of project cash flow.

- Planning follow up.

- Verification of compliance with applicable regulations.

Site management

- Multidisciplinary Site Supervision.

- Planning and Cash Flow Follow up.

- SAT tests, commissioning and start-up.

- Final acceptance and Plant Hand Over.

DISCIPLINES

Process

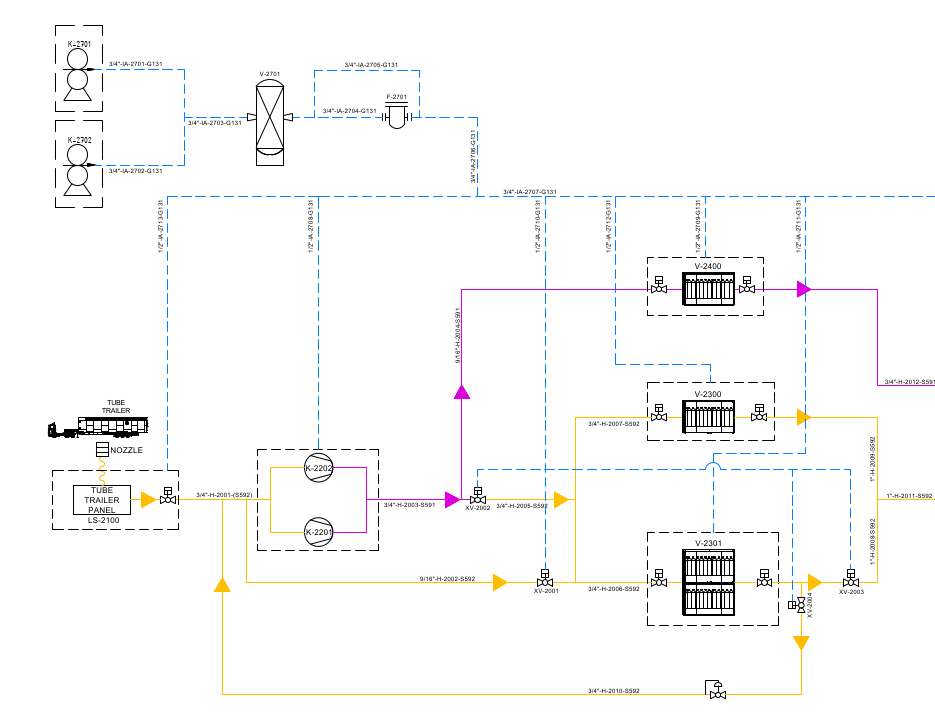

- Development of PFD, P&ID and Operating Modes.

- Process simulation and optimization.

- Hydraulic calculations.

- Mass balances.

- Functional descriptions.

- Thermal calculations.

- Development of Installation, operation and maintenance manuals.

Mechanical

- Specification and selection of main equipment.

- General plant layout.

- Integration and development of 3D model.

- Design and calculation of structures.

- Sizing of PSV and Control Valves.

- Vent Sizing.

Piping

- Development of Piping Class according to EN-13480, ASME B31.3, ASME B31.12.

- Lists and data sheets of pipes and fittings.

- Development of MTO.

- Calculation and desing of Piping supports.

- Flexibility and stress calculations.

- Development of Piping General layout and Isometrics.

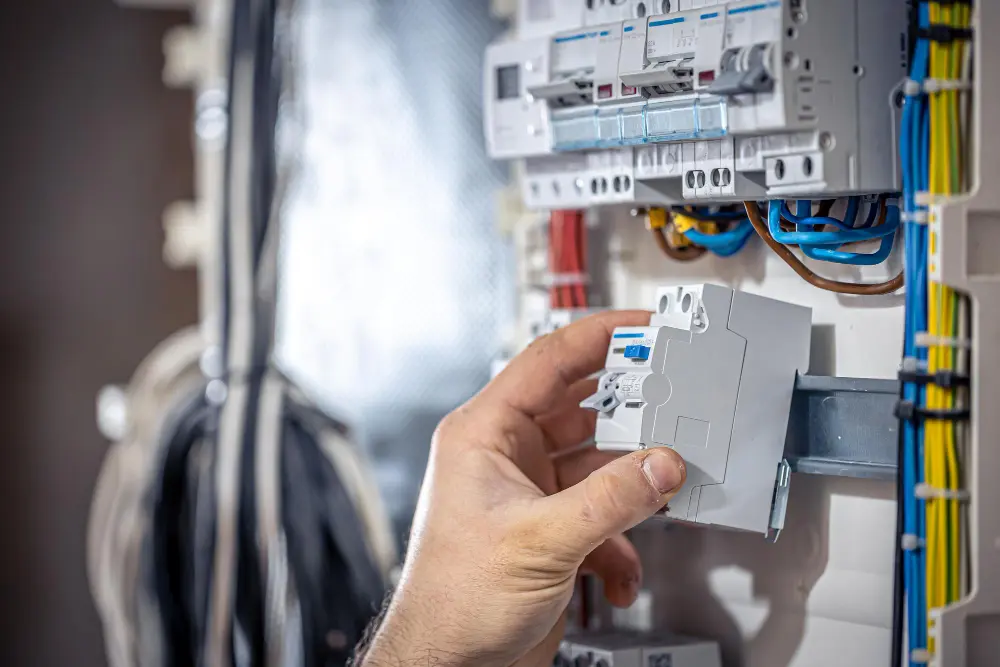

Electrical

- Sizing of Low Voltage cables.

- Specification of electrical substations and transformers.

- Specification of Lighting and Lightning System.

- Lists and data sheets for cables and electrical equipment.

Instrumentation and control

- Development of plant control philosophy.

- Design and development of control and safety system.

- Technical specification of instruments.

- Instrument lists and data sheets.

- Development of plant control architecture.

- Development of control logics.

Safety

- Support and participation in HAZID, HAZOP, SIL, QRA, FERA, EAC studies.

- Development of Hazardous Area Study and drawings.

- Design of Fire and Gas System (F&G).

- Specification of the Fire Figthing system.

We are the alternative to the purchase of bottled gas

Discover our SOLUTIONS with all the advantages it offers!